FLY ASH BRICK PLANT RBM-11

Product Details:

- General Use BRICK PLANT

- Automatic Yes

- Voltage 440 V Volt (v)

- Color Black

- Warranty Yes

- Click to view more

X

FLY ASH BRICK PLANT RBM-11 Price And Quantity

- INR

- 1 Unit

FLY ASH BRICK PLANT RBM-11 Product Specifications

- 440 V Volt (v)

- Black

- Yes

- BRICK PLANT

- Yes

FLY ASH BRICK PLANT RBM-11 Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- All India

Product Description

FLY ASH/CONCRETE BRICK/PAVER MAKING VIBRO-HYDRAULIC PRESS - FULLY AUTOMATIC MACHINE (RBM-11)Electric Motor 10 HP 3PH Crompton / Havells / Kirloskar With Power Pack (Pump of Poly Hydran/Boss &Valve of Yuken/ Poly Hydran . Electric Panel (With Mitsubishi PLC,) Limit Switch/Proximity Sensors, Hopper, Oil Tank Capacity 300 Lit. Cylinder Made by Honed Tube. Piston Is Hard Chrome. Production Capacity 11,000 to 12000 Bricks/Shift and 3000 Blocks/Shift.

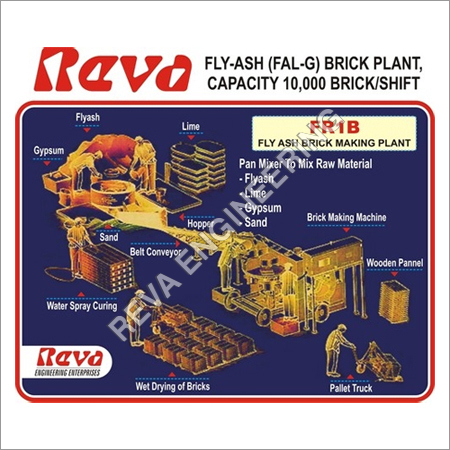

PAN MIXTURE

1 No. Reva Pan Mixer having capacity of 500 Kgs. fitted with 2 Nos. heavy C.I.Rollers, fitted with changeable bottom wear plates fitted with mixing and discharge blades,having special alloy steel tips,complete with quality Worm Reduction Gear Box of Elecon/Roto-Reva powered by 15 H.P./Electric Motor of Kirloskar/Crompton/Havells make With starter.

CONVEYOR

1 No. Reva Belt Conveyor for loading and unloading the material of the Pan Mixer , and powered by 2 H.P.Electric Motor of Havells/Crompton make fitted with quality gear box with starter.The conveyor is fitted with rubber top nylon conveyor belt and is moving on frictionless idlers.

MOULD

(08 Cavity) Eight Bricks per Stroke with frog ( Name in the Brick).

Pallet Trolleys

2 Nos. Reva Pallet Trucks are fitted with Pneumatic Tyres, and manual dragging arrangement with lift capacity of 1000 Kgs.

- Automatic Material Feeder in the Moulds, Hydraulic Operated, Controlled by PLC.

- Automatic Pallet Feeder, Hydraulic Operated, Controlled by PLC.

- Finished Bricks Pallet Conveyor , Powered by 0.5 H.P. Geared Motor.

Efficient Automatic Brick Production

The RBM-11 Fly Ash Brick Plant integrates automatic technology to facilitate a highly productive brick-making process. With its user-friendly controls and dependable workflow, this plant minimizes manual intervention, resulting in consistent quality and substantial savings on labor costs. Its operational efficiency makes it a preferred choice for large-scale brick manufacturers.

Reliable Performance with Warranty

Designed for professional use, the RBM-11 comes with a warranty, ensuring durability and peace of mind. The robust voltage configuration (440 V) supports continuous operation, making it suitable for high-demand environments. The plant is trusted by exporters, manufacturers, and suppliers, and is widely recognized for meeting industry standards throughout India.

FAQs of FLY ASH BRICK PLANT RBM-11:

Q: How does the automatic feature of the RBM-11 Fly Ash Brick Plant improve production efficiency?

A: The automatic functionality significantly reduces manual labor, streamlining the brick-making process and ensuring uniform quality with minimal human intervention. This leads to faster output and reduced chances of production errors.Q: What is the general usage of the RBM-11 Fly Ash Brick Plant?

A: This plant is designed specifically for manufacturing fly ash bricks, which are commonly used in construction projects due to their sustainability, strength, and cost-effectiveness.Q: When is the optimal time to undertake maintenance for the RBM-11?

A: Regular maintenance is best scheduled after every production cycle or as recommended in the manufacturers manual. Periodic servicing helps sustain operational efficiency and extends equipment life.Q: Where can the RBM-11 Fly Ash Brick Plant be installed?

A: The plant can be set up at construction sites, brick manufacturing units, or industrial locations throughout India, as it is engineered for versatile implementation across various scales of production.Q: What is the process for producing fly ash bricks using this plant?

A: Raw materials, including fly ash, cement, and aggregates, are automatically mixed and molded by the machine. The bricks are then compacted, shaped, and cured, ready for use in construction.Q: How is the warranty for the RBM-11 beneficial to users?

A: The warranty provides assurance of product reliability and support for repairs or replacements, helping users maintain uninterrupted production and safeguard their investment.Q: What are the key advantages of using the RBM-11 Fly Ash Brick Plant for exporters and suppliers?

A: Exporters and suppliers benefit from its automated, high-capacity output, consistent product quality, and low operational costs, making it easier to meet bulk order requirements efficiently.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese