Fly Ash Brick Making Machine

75000 INR

Product Details:

- Product Type Brick Making Machine

- General Use Fly Ash Brick Production

- Material Mild Steel

- Capacity 1200 - 1500 Kg/hr

- Weight (kg) 2500 kg

- Type Automatic

- Computerized No

- Click to view more

X

Fly Ash Brick Making Machine Price And Quantity

- 1 Unit

- 75000 INR

- Fly Ash, Cement, Sand, Stone Dust

- Powder Coated

- 2-3 Operators

- Overload Protection, Emergency Stop

- Three Phase Electric

- 300 liters

- 18 - 25 seconds

- Low (85 dB)

- Oil cooling provided

- 8 meters

- Standard 230x110x75 mm, Custom sizes available

Fly Ash Brick Making Machine Product Specifications

- 30 Watt (W)

- 1200 - 1500 Kg/hr

- 4500 - 6000 rpm

- Hydraulic Pressure

- Heavy Duty Vibration Table

- Fly Ash Brick Production

- Blue / Custom

- Optional

- 240 - 320 Volt (v)

- 3400 x 1700 x 2300 mm

- 2500 kg

- 75 mm

- Brick Making Machine

- No

- Energy Efficient, Robust Construction

- 100 - 120 Ton

- Mild Steel

- 4/6/8 bricks per cycle

- Automatic

- 230 mm

- Yes

- 600 x 300 mm

- Fly Ash, Cement, Sand, Stone Dust

- Powder Coated

- 2-3 Operators

- Overload Protection, Emergency Stop

- Three Phase Electric

- 300 liters

- 18 - 25 seconds

- Low (85 dB)

- Oil cooling provided

- 8 meters

- Standard 230x110x75 mm, Custom sizes available

Fly Ash Brick Making Machine Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- Carton Box

- All India

Product Description

Our superior quality Fly Ash Brick Making Machine has huge demand all over the world. We manufacture and export this machine under the supervision of competent professionals. The premium quality of this machine has been verified on the basis of its durability and functional life. It is extensively used in construction industry for production of fly ash bricks. Our Fly Ash Brick Making Machine can be obtained at affordable price range.

Major Market:- Kolkata,Orisa and Chhatisgarh

Features:

- High productivity level

- Vibration free operation

- Long working life

- The quality of used raw materials

- Mechanism of machinery

- Reva Machines are useful for producing standard grade bricks

- Size 200 x 100 x 100 mm Standard

- Size 250 X 120 x 75 mm Standard

- Size 230 x 110 x 75 mm Standard

- Size 230 x 110 x 75 mm Chamfered

Technical Specifications:-

- PLC operated completely automatic function

- Well built structure

- The size of fly ash bricks ranges between 4 inch to 6 inch

- Molds are of interchangeable system

- The quality of produced bricks conforms to IS: 4139:1989 & 12894:1990 standard

- Its compressive strength is up to 6 N/ Sq mm

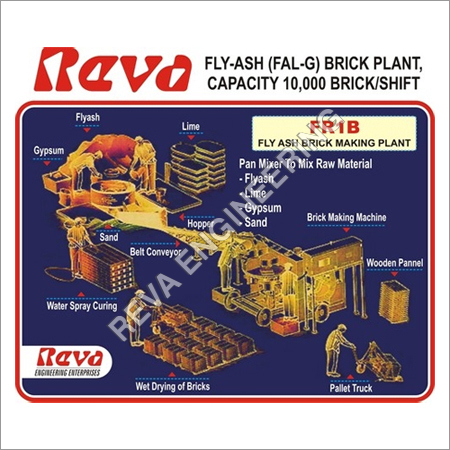

Raw Material:-

| Raw material | |

| Fly ash | 50 % |

| Lime | 15 % |

| Gypsum | 5% |

| Sand or dust | 30% |

| Water as per requirement | |

Advantages of Fly ash brick:-

- Reckoned for better capacity/strength when compared to ordinary clay bricks

- Better salt and water resistance capacity than ordinary bricks

- Low weight when compared to normal bricks

- Proper shape and size. Unique durability.

Machine Specification:-

| Machine Specification | |

| Bricks Production | 14,000 Bricks/ 8 Hrs. |

| Mixer Gear Box Material | Steel |

| Crushing Rollers | Heavy Duty Crushing Rollers with Vertical Spring Suspensions. |

| Conveyor belt length | 21 ft. |

| Conveyor Bin Storage Capacity | 1400 K.G. |

| Pallet Trucks Capacity | 500 K.G. |

| Control Panel Type | Programmable Logic Controller (PLC) Assisted Control Panel. |

| Standard Brick Size | 230 X 110 X 75 mm |

| Maximum Brick Size | 230 X 110 X 100 mm |

Advanced Hydraulic & Vibration System

This brick making machine utilizes a hydraulic pressure mechanism paired with a heavy-duty vibration table operating at 45006000 rpm. Such combination guarantees dense and durable fly ash bricks, suitable for various construction needs. Its maximum pressure capacity reaches up to 120 tons, contributing to uniformly molded bricks every cycle.

Optimized Production & Energy Efficiency

Capable of producing 12001500 kg of bricks per hour, the machine ensures high output with low labor requirementsjust 23 operators needed. The energy-efficient design, supported by a 30 Watt power system, minimizes operational costs while maintaining peak productivity throughout long manufacturing shifts.

Robust Construction & Customization

Built from mild steel and powder-coated for enhanced durability, the machine offers robustness against wear and tear. It accepts both standard (230x110x75 mm) and custom brick sizes, and its conveyor belt extends 8 meters for streamlined workflow. Color customization options accommodate branding preferences.

FAQs of Fly Ash Brick Making Machine:

Q: How does the Fly Ash Brick Making Machine operate and what materials are required?

A: The machine uses hydraulic pressure and a heavy-duty vibration table to compact fly ash, cement, sand, and stone dust into bricks. Operation is automatic, requiring only 23 operators and a three-phase electric power source. The materials are fed into the machine, which then produces bricks through its rapid cycle time of 1825 seconds.Q: What customization options are available for brick sizes and machine features?

A: Standard brick size accommodation is 230x110x75 mm, but the machine can be configured for custom sizes. Pallet dimensions and brick height can be adjusted within specified limits (75230 mm), and color customization for the machine is available to suit branding requirements. Optional PLC control enhances automation capabilities.Q: When should the oil tank and cooling system be maintained?

A: Regular maintenance of the 300-liter oil tank and integrated oil cooling system is recommended according to usage intensitytypically every 36 months for optimal performance. Ensuring proper oil levels and cooling efficiency helps maintain consistent hydraulic pressure and prolongs machine lifespan.Q: Where is this Fly Ash Brick Making Machine suitable for installation?

A: The machine is designed for industrial environments with adequate space (dimensions: 3400 x 1700 x 2300 mm) and access to three-phase electric power. It is commonly installed at brick manufacturing plants, construction sites, or factories engaged in bulk fly ash brick production across urban and rural India.Q: What is the brick production process using this machine?

A: Operators load fly ash, cement, sand, and stone dust into the appropriate feed. The machine then hydraulically presses and vibrates the mix in molds, forming 4, 6, or 8 bricks per cycle. Bricks are ejected onto the conveyor belt, streamlining transfer for stacking or curing.Q: How does the machine ensure safety during operation?

A: Built-in safety features include overload protection and an emergency stop mechanism. These prevent damage or injury in case of power surges, overpressure, or operator incidents, ensuring safe and reliable production at noise levels 85 dB.Q: What are the main benefits of using this Fly Ash Brick Making Machine?

A: Primary benefits include high-volume output (12001500 Kg/hr), energy efficiency, minimal labor requirements, robust construction, customizable production, and advanced safety mechanisms. Its automatic operation speeds up manufacturing while maintaining consistent brick quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese