Automatic Fly Ash Brick Plant

Product Details:

- General Use Brick Plant

- Weight (kg) 2 Ton Long Ton

- Automatic Yes

- Color Blue

- Warranty Yes

- Click to view more

Automatic Fly Ash Brick Plant Price And Quantity

- 1 Unit

- INR

Automatic Fly Ash Brick Plant Product Specifications

- Brick Plant

- Yes

- 2 Ton Long Ton

- Yes

- Blue

Automatic Fly Ash Brick Plant Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- All India

Product Description

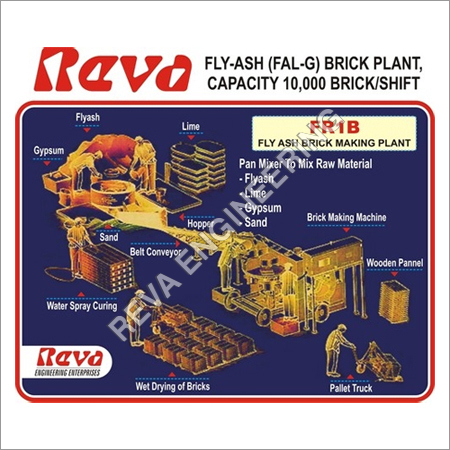

The offered Automatic Fly Ash Brick Plant has been specially developed to meet diverse requirements of construction industry. This specific plant has huge demand around the world for its durable nature. This plant is developed by skilled professionals by utilizing premium quality raw materials. This automatically operated Automatic Fly Ash Brick Plant can be obtained at affordable price range.

Features

- High productivity

- Exceptional vibration resistance properties

- Long working life

AUTOMATIC FLY-ASH/CONCRETE BRICK /BLOCK MAKING HYDRAULIC PRESS FULLY AUTOMATIC

Model No. : RBM-30

Notable for its robust structure, this machine consists of four shafts to safeguard the Ram punch of mold, Mitsubishi PLC controlled electric panel, proximity sensors or limit switch, honed tube fabricated cylinder, hopper, hard chrome plated piston, mold vibrator with 7.5 H.P, motor, automatically operated pallet feeder and material feeder. The production capacity of this hydraulically regulated machine is 27,000 to 30,000 bricks per shift.

ELECTRICAL CONTROL PANEL

Its Mitshubishi HMI and PLC operated control panel is equipped with MCC, Schneider electric switchgear, relay control system, various accessories and connectors.

Hydraulic System

It is designed with hydraulic power pack with 400 ltr capacity, Douty Gear Pump, Flange type motor and Yuken valves. The oil filters of this system are located at its outgoing, incoming and return line. Its 25HP 3PH Havells/Crompton electric motor is featured with water cooler and power pack system.

Brick Mould

(24 Cavity). 24 Bricks/Stroke with Frog (Name in Brick).

Pan Mixer

The 1000 kgs capacity 'REVA' Pan Mixer is attached to two heavy duty C.I. Rollers that are joined with changeable bottom wear plates. These bottom wear plates are connected with mixing and discharge blades with special alloy steel made tips. The mixer also contains advanced Worm Reduction Gear Box of Elecon/Radicon brand and it is driven by Kirloskar/Havells/Crompton made 30 H.P. Electric motor with Star-Delta starter.

Belt Conveyor

The25ft long 'REVA' belt conveyor comes in handy for transportation of mixing materials of Pan Mixer. This belt conveyor is driven by Crompton/Kirloskar made 3 H.P. Electric motor with is attached to starter equipped gear box. The conveyor is joined with nylon conveyor belt with rubber made surface and it moves on frictionless idlers.

Pallet Trolleys

Six 'REVA' Pallet Trucks are attached to hydraulic lifting system, manual pumping system and pulling system. The lifting capacity of these trolleys is 1000 kgs produced bricks.

Finished Brick conveying Conveyor

The 12 feet conveying conveyor is driven by 1 H.P. Geared motor

Automatic Batching System

The weight of raw materials of Belt Conveyor is determined by Load Cells and Automatic Batch Control system with computer printing facility and one week data storing system. Apart from its self regulated raw materials discharging system, this Automatic Batching System is featured with 7.5 H.P, Geared Motor and H.P. Chute Vibrator.

Automatic Stacker

The Automatic Stacker is required for transportation of brick pallets. It is driven by 01+02 H.P. Electric motor and is regulated by variable frequency drive. Its mini material loader is used for feeding material in its batching system.

Efficient Brick Manufacturing

The Automatic Fly Ash Brick Plant revolutionizes the process of brick making by leveraging automation for uniformity and speed. Its advanced design minimizes human intervention and maximizes output, making it suitable for large-scale industrial use in India. The plant can handle substantial volumes efficiently due to its sturdy 2-ton construction and modern controls.

Durable and Reliable Operation

Built to withstand rigorous industrial demands, this brick plant incorporates strong materials and offers a warranty to guarantee performance. Its blue exterior not only enhances aesthetics but also reflects its robust engineering. Users benefit from peace of mind, knowing their investment is supported by comprehensive after-sales service.

FAQs of Automatic Fly Ash Brick Plant:

Q: How does the automatic fly ash brick plant operate?

A: The plant functions via an automated system that manages brick molding, pressing, and curing. It uses fly ash and other raw materials to produce bricks with minimal manual intervention, ensuring consistent quality and high output.Q: What is the primary usage of this brick plant?

A: This machine is designed for the industrial production of bricks, primarily in large-scale construction projects. It streamlines the manufacturing process, significantly reducing labor requirements compared to manual brick plants.Q: When should I consider installing an automatic fly ash brick plant?

A: Installation is ideal when scaling up brick production or transitioning from manual methods to automated processes to improve efficiency, product quality, and output volume, particularly in regions with demand for fly ash bricks.Q: Where is this automatic brick plant available?

A: The plant is readily available across India, distributed by reputable exporters, manufacturers, suppliers, and traders who cater to a range of business needs and project sizes.Q: What is the process involved in making bricks with this plant?

A: Raw materials, including fly ash, are automatically weighed, mixed, and poured into molds. The plant then compresses and shapes the bricks, followed by a curing phase, resulting in durable finished products ready for shipment.Q: What are the benefits of using an automatic fly ash brick plant over manual alternatives?

A: Benefits include increased productivity, consistent brick quality, reduced labor costs, and a more streamlined manufacturing process. The automated system ensures optimal material utilization and minimizes waste.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese