FLY ASH BRICK PLANT RBM-18

Product Details:

- General Use Brick Plant

- Automatic Yes

- Feature High Durability

- Color Blue

- Warranty Yes

- Click to view more

FLY ASH BRICK PLANT RBM-18 Price And Quantity

- 1 Unit

- INR

FLY ASH BRICK PLANT RBM-18 Product Specifications

- High Durability

- Brick Plant

- Yes

- Blue

- Yes

FLY ASH BRICK PLANT RBM-18 Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 1 Unit Per Month

- 2 Months

- All India

Product Description

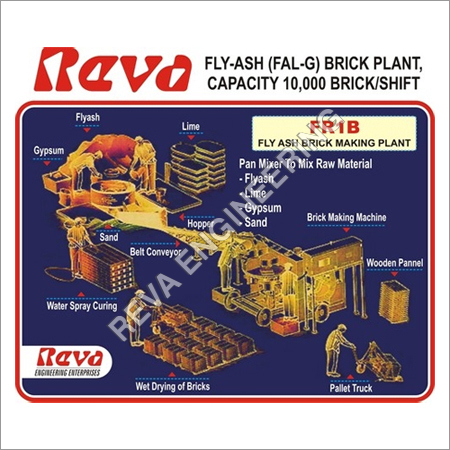

| FLY-ASH/CONCRETE BRICK /BLOCK MAKING YDRAULIC PRESS FULLY AUTOMATIC M/ C. (RBM-18) Electric Motor 15HP 3PH of Crompton / Havells, Complete With Power Pack (Pump of Douty/Boss &Valve of Yuken/ Poly Hydran . Electric Panel (With Messung Systems PLC,) Limit Switch/Proximity Sensors, Hopper, Oil Tank Capacity 400 Lit. Cylinder Made by Honed Tube. Piston Is Hard Chrome. Production Capacity 22,000 TO 23,000 Bricks/Shift of standard size. 5 H.P. Mould Vibrator. PAN MIXTURE 1 No. Reva Pan Mixer having capacity of 1000 Kgs. fitted with 2 Nos. heavy C.I.Rollers, fitted with changeable bottom wear plates fitted with mixing and discharge blades,having special alloy steel tips,complete with quality Worm Reduction Gear Box Elecon/Radicon make powered by 30 H.P./Electric Motor of Kirloskar/Crompton/Havells make With starter.

CONVEYOR 1 No. Reva Belt Conveyor for loading and unloading the material of the Pan Mixer of app. 20 ft.and powered by 3 H.P.Electric Motor of Kirlostar/Crompton make fitted with quality gear box with starter.The conveyor is fitted with rubber top nylon conveyor belt and is moving on frictionless idlers.

MOULD (18 Cavity). 18 Bricks/Stroke with Frog (Name in Brick).

Pallet Trucks 3 Nos. Reva Pallet Trucks are fitted with 03 nos. pneumatic tyres and manual dragging arrangement with lift capacity of 1000 Kgs.

Automatic Material Feeder, Hydraulic Operated

Automatic Pallet Feeder, Hydraulic Operated

|

Engineered for Longevity and Reliability

The RBM-18 fly ash brick plant stands out for its exceptional durability, thanks to high-grade materials and advanced engineering. Its robust construction ensures the machine operates efficiently under demanding industrial conditions, making it a dependable choice for continuous brick production.

Fully Automatic for Efficient Production

With its automatic operation, the FLY ASH BRICK PLANT RBM-18 streamlines the brick-making process, minimizing labor requirements and maximizing output. Users benefit from consistent brick quality and substantial time savings, making it ideal for high-volume production environments.

Comprehensive Warranty & Quality Support

Each RBM-18 unit comes with a warranty, assuring users of the manufacturers commitment to product quality and after-sales service. Our dedicated support team ensures any concerns are addressed promptly, keeping your operations smooth and worry-free.

FAQs of FLY ASH BRICK PLANT RBM-18:

Q: How does the RBM-18 Fly Ash Brick Plant work?

A: The RBM-18 operates automatically, using fly ash and other raw materials to produce uniform bricks. The machine requires minimal manual intervention, automating tasks such as material feeding, molding, and brick ejection for efficient and consistent production.Q: What benefits does the high durability of the RBM-18 offer?

A: High durability means the plant withstands continuous operation in demanding conditions, ensuring a longer service life and reduced maintenance costs. This reliability translates into higher productivity and return on investment for brick manufacturers.Q: When should I choose an automatic fly ash brick plant like the RBM-18?

A: The RBM-18 is ideal when high productivity, reduced labor costs, and consistent quality are priorities. It is especially suited for businesses aiming to scale up or modernize their brick manufacturing operations.Q: Where is the RBM-18 primarily used?

A: This brick plant is generally used in industrial brick manufacturing facilities across India and is also exported to several countries. Its suitable for any setting requiring the efficient production of fly ash bricks.Q: What is the process of installing the RBM-18 at my facility?

A: Our team provides guidance throughout the installation process. After delivery to your site, technicians assist in assembling and setting up the RBM-18, ensuring it is operational quickly and safely.Q: How does using fly ash bricks benefit construction projects?

A: Fly ash bricks produced by the RBM-18 are eco-friendly, cost-effective, and have high compressive strength. Their consistent quality and size contribute to faster, safer, and more sustainable construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese