FLY ASH BRICK PLANT RBM-25

Product Details:

- Product Type Fly Ash Brick Plant

- General Use BRICK PLANT

- Material Mild Steel

- Capacity 2500-3000 Bricks/Hour

- Weight (kg) 3500 kg

- Type Semi-Automatic

- Computerized No

- Click to view more

X

FLY ASH BRICK PLANT RBM-25 Price And Quantity

- INR

- 1 Unit

- 68 Grade

- 230 x 110 x 75 mm

- Less Than 75 db

- 12-15 Seconds

- 8-10 Hours

- 3-4 Persons

- 250 Litres

FLY ASH BRICK PLANT RBM-25 Product Specifications

- Blue & Yellow

- Hydraulic Pressure

- 3600 RPM

- 3500 kg

- Fly Ash Brick Plant

- 230 mm

- 2500-3000 Bricks/Hour

- 440 V

- 2300 x 2200 x 2700 mm

- Semi-Automatic

- Mild Steel

- Table Vibration

- 75 mm

- 27 HP

- 6 / Stroke

- No

- 600 x 300 x 18 mm

- BRICK PLANT

- 200 Ton

- High Durability, Low Maintenance, Robust Construction

- Semi-Automatic

- No

- 68 Grade

- 230 x 110 x 75 mm

- Less Than 75 db

- 12-15 Seconds

- 8-10 Hours

- 3-4 Persons

- 250 Litres

FLY ASH BRICK PLANT RBM-25 Trade Information

- 1 Unit Per Month

- 2 Months

Product Description

AUTOMATIC HYDRAULIC BRICK MACHINE RBM-25Heavy structure body with four nos. of shaft to guide the Ram Punch of Mould, Electric Panel (With Mitsubishi PLC,) Limit Switch/Proximity Sensors, Hopper, Cylinder Made by Honed Tube. Piston Is Hard Chrome. Production Capacity 24,000 to 26,000 Bricks/Shift. 7.5 H.P. Mould Vibrator.

Automatic material feeder and Pallet Feeder, Hydraulic operated, controlled by PLC.

Hydraulic Power pack of 400 Ltr. Capacity, with Flange type motor, Douty Gear Pump, Yuken Valves, Oil filters at Incoming , outgoing and return line. Electric Motor 20HP 3PH of Crompton / Havells, Complete With Power Pack , Water cooler arrangement.

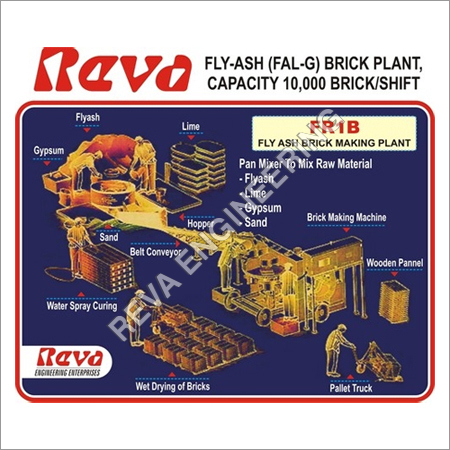

PAN MIXTURE

2 Nos. Reva Pan Mixer having capacity of 550 Kgs. fitted with 2 Nos. heavy C.I.Rollers, fitted with changeable bottom wear plates fitted with mixing and discharge blades, having special alloy steel tips, complete with quality Worm Reduction Gear Box Elecon/Radicon make powered by 15 H.P./Electric Motor of Kirloskar/Crompton/Havells make

With Star-Delta starter.

CONVEYOR

1 No.Reva Belt Conveyor for loading and unloading

the material of the Pan Mixer of app. 25 ft.and powered by 3 H.P.Electric Motor of Havells / ABB/ Siemens/Bharat Bijlee make fitted with quality gear box with starter. The conveyor is fitted with rubber top nylon conveyor belt and is moving on frictionless idlers

MOULD

(21 Cavity). 21 Bricks/Stroke with Frog (Name in Brick).

Pallet Trucks

4 Nos. Reva Pallet Trucks are fitted with hydraulic lifting, hand pumping and manual dragging arrangement with lift capacity of 1000 Kgs.

- Automatic Material Feeder, Hydraulic Operated

- Automatic Pallet Feeder, Hydraulic Operated

- Finished Fly-Ash Bricks Pallet Conveyor , powered by 0.5 H.P. Geared Motor.

High-Performance Hydraulic Technology

Built with advanced hydraulic pressure and table vibration mechanisms, the RBM-25 ensures even compaction and precise shaping of each brick. Its high-pressure capacity of up to 200 tons and rapid pressing cycle allow manufacturers to maintain an efficient workflow throughout each production shift.

User-Friendly and Durable Design

This semi-automatic plant demands only 3-4 operators and focuses on ease of use. Fabricated from mild steel for added resilience and finished with vibrant colors, the RBM-25 combines longevity, low maintenance requirements, and straightforward operation, ensuring reliable service for various production environments.

FAQs of FLY ASH BRICK PLANT RBM-25:

Q: How does the RBM-25 fly ash brick plant operate?

A: The RBM-25 uses hydraulic pressure and table vibration to produce fly ash bricks. Feed materials are loaded onto pallets, after which the hydraulic system compresses them with up to 200 tons of pressure. The table vibration at 3600 RPM further compacts the mix, resulting in well-formed bricks every 12-15 seconds.Q: What is the maximum production capacity of this brick plant per hour?

A: This plant can produce between 2500 and 3000 standard-sized bricks per hour, depending on operator efficiency and material availability, making it highly suitable for medium to large-scale brick manufacturing businesses.Q: When is it necessary to change or refill the hydraulic oil in the RBM-25?

A: Hydraulic oil should be checked regularly for contamination and replaced as per the manufacturers guidelines, typically after every few months of continuous use. Always use 68-grade oil for optimal performance and machine longevity.Q: Where is the RBM-25 model especially effective for use?

A: The RBM-25 is designed for use in industrial and commercial brick manufacturing environments across India, suitable for exporters, manufacturers, suppliers, and traders requiring robust and reliable brick production equipment.Q: What is the process for producing bricks with the RBM-25?

A: Raw materials are mixed and fed into the machine, which presses them under high hydraulic pressure. The vibratory table ensures effective compaction, producing six standard bricks per stroke. The process repeats with minimal operator intervention due to the machines semi-automatic controls.Q: Which features make this brick plant beneficial for manufacturers?

A: Notable benefits include its high durability, low maintenance needs, large daily output, robust construction, and reduced noise levels. The plants semi-automatic operation allows manufacturers to maximize productivity while minimizing labor and operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese