FLY ASH BRICK PLANT RBM-35

Product Details:

- General Use BRICK PLANT

- Capacity 1000-1500 Kg/hr

- Automatic Yes

- Color Blue

- Warranty Yes

- Click to view more

FLY ASH BRICK PLANT RBM-35 Price And Quantity

- 1 Unit

- INR

FLY ASH BRICK PLANT RBM-35 Product Specifications

- 1000-1500 Kg/hr

- Blue

- Yes

- Yes

- BRICK PLANT

FLY ASH BRICK PLANT RBM-35 Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- All India

Product Description

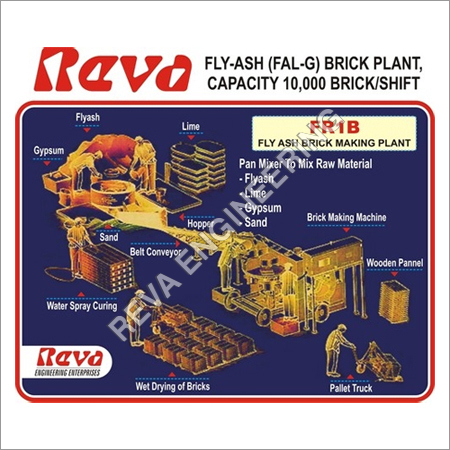

| AUTOMATIC HYDRAULIC BRICK MACHINE RBM-25 Heavy structure body with four nos. of shaft to guide the Ram Punch of Mould, Electric Panel (With Mitsubishi PLC,) Limit Switch/Proximity Sensors, Hopper, Cylinder Made by Honed Tube. Piston Is Hard Chrome. Production Capacity 32,000 to 36,000 Bricks/Shift. 10 H.P. Mould Vibrator. Automatic material feeder and Pallet Feeder, Hydraulic operated, controlled by PLC.

Hydraulic Power pack of 400 Ltr. Capacity, with Flange type motor, Douty Gear Pump, Yuken Valves, Oil filters at Incoming , outgoing and return line. Electric Motor 20HP 3PH of Crompton / Havells, Complete With Power Pack , Water cooler arrangement.

PAN MIXTURE 2 Nos. Reva Pan Mixer having capacity of 700 Kgs. fitted with 2 Nos. heavy C.I.Rollers, fitted with changeable bottom wear plates fitted with mixing and discharge blades, having special alloy steel tips, complete with quality Worm Reduction Gear Box Elecon/Radicon make powered by 20 H.P./Electric Motor of Kirloskar/Crompton/Havells make With Star-Delta starter. CONVEYOR 1 No. Reva Belt Conveyor for loading and unloading the material of the Pan Mixer of app. 25 ft.and powered by 3 H.P.Electric Motor of Havells / ABB/ Siemens/Bharat Bijlee make fitted with quality gear box with starter. The conveyor is fitted with rubber top nylon conveyor belt and is moving on frictionless idlers

MOULD (27 Cavity). 27 Bricks/Stroke with Frog (Name in Brick).

Pallet Trucks 3 Nos. Reva Pallet Trucks are fitted with hydraulic lifting, hand pumping and manual dragging arrangement with lift capacity of 1000 Kgs.

Automatic Material Feeder, Hydraulic Operated

Automatic Pallet Feeder, Hydraulic Operated

Finished Fly-Ash Bricks Pallet Conveyor , powered by 0.5 H.P. Geared Motor. |

High-Capacity Automated Brick Production

The RBM-35 exemplifies automation and productivity, delivering an output of 1000-1500 kilograms per hour. Its robust construction and fully automated operation streamline the manufacturing process, making it perfect for businesses looking to enhance efficiency and reduce manual labor.

Trusted Indian Manufacturer and Exporter

Manufactured in India, the RBM-35 benefits from high-quality engineering standards. It is supplied and exported worldwide, supported by reliable after-sales service and warranty, making it a worthwhile investment for businesses across the globe.

FAQs of FLY ASH BRICK PLANT RBM-35:

Q: How does the FLY ASH BRICK PLANT RBM-35 operate automatically?

A: The RBM-35 plant utilizes advanced automated systems to manage the mixing, molding, and curing of fly ash bricks. This reduces the need for manual intervention, ensures consistent quality, and streamlines the entire production process.Q: What are the primary usages of the RBM-35 Brick Plant?

A: The RBM-35 is primarily used for manufacturing fly ash bricks, which are utilized extensively in the construction industry for building walls, pavements, and other structural components.Q: When should I consider using the RBM-35 over other brick-making machines?

A: If you require high output (1000-1500 kg/hr), minimal manual labor, and seek reliability backed by a warranty, the RBM-35 is an excellent choice. Its automation is ideal for operations aiming to scale up their production efficiently.Q: Where is the RBM-35 manufactured and available for export?

A: The RBM-35 is produced in India and is available for export, supply, and trading worldwide. The plants manufacturer ensures comprehensive support for both domestic and international clients.Q: What is the process involved in making bricks with the RBM-35?

A: The process includes automatic feeding and mixing of raw materials (such as fly ash, sand, and cement), molding into specific brick shapes, compacting, and finally curing, all handled by the integrated automated system.Q: What are the benefits of choosing a fully automatic fly ash brick plant like the RBM-35?

A: Opting for the RBM-35 means achieving uniform brick quality, higher production rates, and significant savings on manpower. Automation also minimizes operational errors and downtime, which contributes to overall cost-effectiveness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese