Concrete Brick Making Plant

Product Details:

- General Use Making Plant

- Capacity 500-1000 T/hr

- Automatic Yes

- Color Purple

- Warranty Yes

- Click to view more

X

Concrete Brick Making Plant Price And Quantity

- INR

- 1 Unit

Concrete Brick Making Plant Product Specifications

- Purple

- Yes

- Yes

- Making Plant

- 500-1000 T/hr

Concrete Brick Making Plant Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- All India

Product Description

With having years of business experience, we are engaged in offering wide assortment of Concrete Brick Making Plant. This ergonomically designed machine has been developed by using latest equipments that are in sync with industry specified standards. This plant is required for conducting various heavy duty works. Our Concrete Brick Making Plant is preferred for its unique strength, stable operation, rust and abrasion proof design, minimum maintenance cost and trouble free operation.

Other Details :

Features

Details

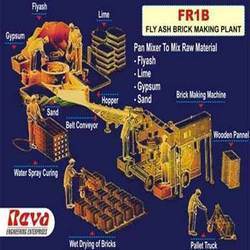

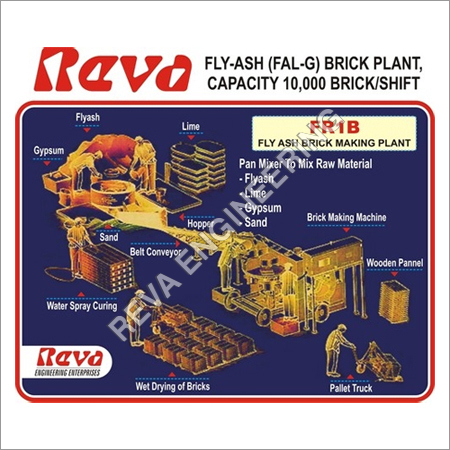

PAN Mixture

The 'REVA' pan mixer with 300 kg mixing capacity is attached to two heavy duty C.I, rollers and these rollers are connected to easy to change bottom wear plates. These bottom wear plates are connected with discharging and mixing blades that consist of alloy steel made tips and premium quality worm reduction gear box of Roto-Reva. This worm reduction gear is driven by 7.5/10 H.P./electric motor belonging to ABB/Crompton/Havells/Kirloskar brand with starter.

Conveyor

The 'REVA' belt conveyor is used for loading and unloading of mixing material of pan mixer. This type of conveyor is driven by Crompton/Havells electric motor with 3 H.P capacity and is attached to a starter equipped gear box. The conveyor is connected to nylon conveyor belt with rubber made surface and it rotates on frictionless idlers.

Finished Bricks Moving Conveyor

The 'REVA' Pallet Conveyor is instrumental for forward movement of bricks on pallets and it is controlled by H.P. Geared Motor.

Mold

Each stroke of its mold can develop six bricks

Pallet trucks

Two 'REVA' pallet trucks are attached to pneumatic tyres and these are connected to manually operated dragging system with 1000 kgs of lifting capacity.

Other Details :

Features

- It consists of material feeder with self regulating mechanism and its is known for its PLC operated hydraulic function

- The automatic pallet feeder of this plant is regulated by PLC and is driven by hydraulic system

- The produced bricks are transported by its conveyor

- Its automatic color feeder is equipped with hopper and color mixer

- Energy efficient operation

- It does not emit any dust

- Accurate dimension and well built structure

- Exceptional electricity conductivity

- Advanced ,operation controlling system

- Minimum frictional co-efficiency rate and low wear rate

- Uninterrupted operation

Details

- This plant uses 10HP 3PH electric motor of Havells/Crompton/Kirloskar with power Pack (Boss & Valve of Yuken/Poly Hydran/Pump of Poly Hydran)

- Its electric panel is designed with PLC operated Messung System, hopper, limit switch or proximity sensors and oil tank with 300 liters of storage capacity

- Honed tube fabricated cylinder, hard chrome plated piston. The offered plant is capable fo producing 8,000 to 10,000 bricks per shift

- Its automatic material feeder is regulated by PLC and driven by hydraulic system

- Conveyor for transportation of manufactured bricks

PAN Mixture

The 'REVA' pan mixer with 300 kg mixing capacity is attached to two heavy duty C.I, rollers and these rollers are connected to easy to change bottom wear plates. These bottom wear plates are connected with discharging and mixing blades that consist of alloy steel made tips and premium quality worm reduction gear box of Roto-Reva. This worm reduction gear is driven by 7.5/10 H.P./electric motor belonging to ABB/Crompton/Havells/Kirloskar brand with starter.

Conveyor

The 'REVA' belt conveyor is used for loading and unloading of mixing material of pan mixer. This type of conveyor is driven by Crompton/Havells electric motor with 3 H.P capacity and is attached to a starter equipped gear box. The conveyor is connected to nylon conveyor belt with rubber made surface and it rotates on frictionless idlers.

Finished Bricks Moving Conveyor

The 'REVA' Pallet Conveyor is instrumental for forward movement of bricks on pallets and it is controlled by H.P. Geared Motor.

Mold

Each stroke of its mold can develop six bricks

Pallet trucks

Two 'REVA' pallet trucks are attached to pneumatic tyres and these are connected to manually operated dragging system with 1000 kgs of lifting capacity.

Efficient Automation

This plant boasts a fully automatic system, minimizing manual labor and maximizing productivity. Its modern controls manage raw material feeding, molding, and output, ensuring uniform and high-quality concrete bricks every cycle, elevating both speed and consistency on the production floor.

Robust Production Capacity

With the capacity to produce 500 to 1000 tonnes per hour, this concrete brick making plant is engineered to meet the demands of large-scale projects. Its fast throughput makes it highly suitable for suppliers who need to fulfill bulk orders efficiently and maintain competitive delivery timelines.

Reliable Support and Longevity

Each unit comes with a warranty, offering assurance of durability and ongoing support. The plants construction and after-sales service are tailored to the needs of Indian exporters, manufacturers, and traders, ensuring long-term operational stability and customer satisfaction.

FAQs of Concrete Brick Making Plant:

Q: How does the automatic feature of the concrete brick making plant enhance production?

A: The fully automatic system streamlines the manufacturing process by handling material feeding, molding, and brick ejection, reducing manual intervention. This increases production speed, ensures consistency in brick quality, and minimizes the risk of human error.Q: What is the process involved in making bricks using this plant?

A: Raw materials are automatically fed into the mixer, where they are blended thoroughly. The mixture is then transferred into molds under hydraulic pressure to form bricks, which are cured and ejected automatically, ready for further handling or storage.Q: When is it most beneficial to use a plant with a 5001000 T/hr capacity?

A: Such high-capacity plants are ideal for large-scale construction projects, export demands, or when supplying to multiple distribution channels frequently. It ensures timely fulfillment of sizable orders and boosts operational efficiency.Q: Where can this purple concrete brick making plant be installed?

A: This plant is designed for versatile installation at manufacturing units, large construction facilities, or suppliers yards across India. Its robust build accommodates both urban and remote production sites.Q: What advantages does the warranty provide to users?

A: The warranty offers peace of mind by covering production-related defects or mechanical issues, ensuring uninterrupted operation and support from the manufacturer through professional maintenance services.Q: How does this plant benefit exporters and traders in India?

A: By delivering high output and consistent brick quality, exporters and traders can meet international standards and bulk order requirements reliably, giving them a competitive advantage in the market.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fly Ash Brick Plant' category

|

REVA ENGINEERING ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese